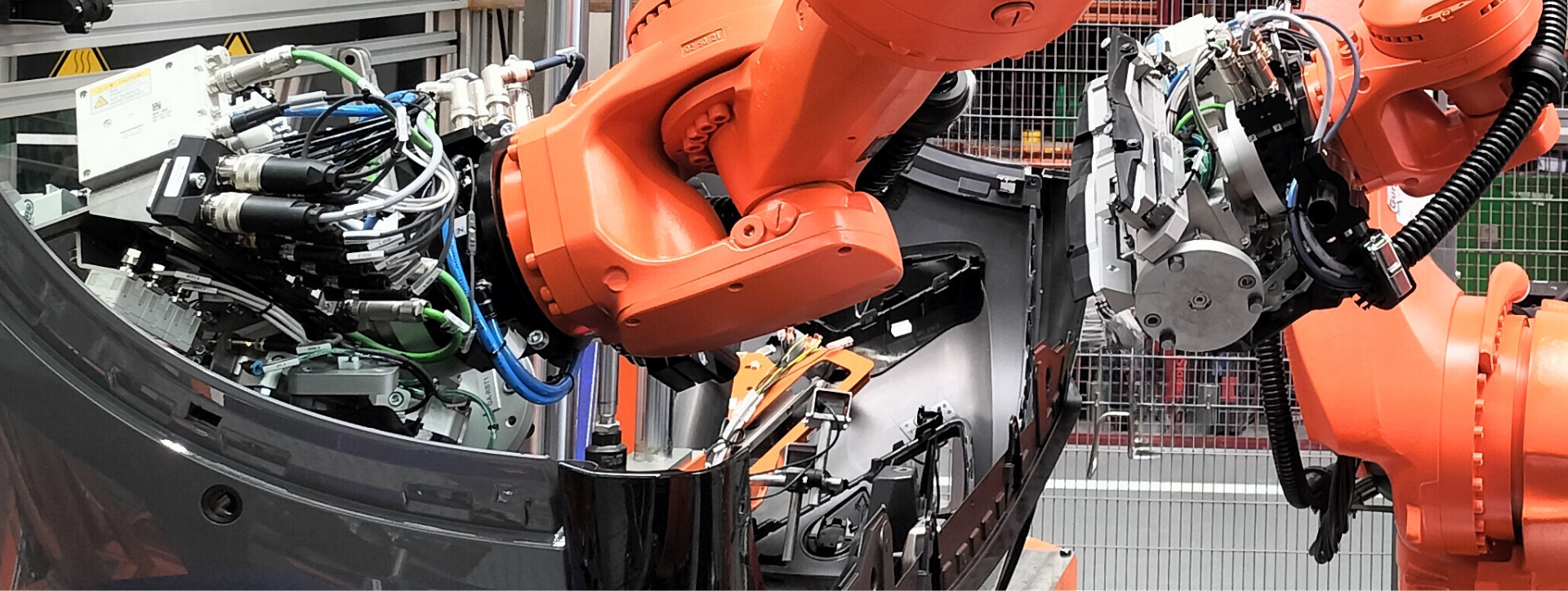

Installation developed for the automation of the inspection of welds by X-rays for the aeronautical sector. The process is carried out by two robots, one of them positions the digital film which, when exposed to the X-ray gun of the other robot, reveals the image of the weld for subsequent analysis. The entire process is carried out in a bunker to protect from radiation.

Design of cribs printed in 3D and post processed with fiber and resin. The additive manufacturing process has made it possible to obtain very light and resistant cradles. This allows to increase the speed of the robot when positioning and reduce the cycle time.

2-AXIS TURN TABLE

2-axis table system that orients the piece by interpolating the movement with the robot that positions the films

3D CRIB WAREHOUSE

Cradle magazine with adaptable geometries to part surfaces.

FILM FEEDER

Digital film store that feeds the robot with the right size in each phase.

BUNKER EXIT SYSTEM

Film output system outside the bunker for scanning and analysis.