RETROFIT ENGRAVED TRIVALENT EMERGENCY FRAME

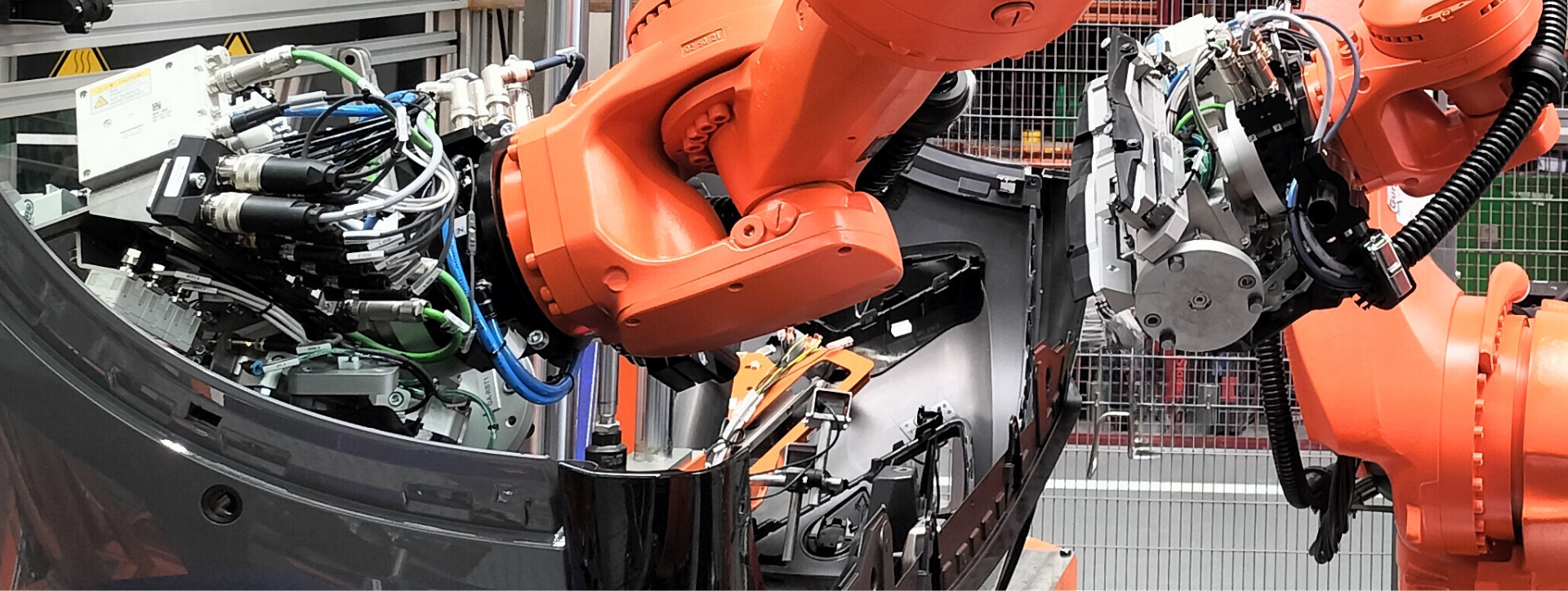

Retrofit developed to adapt the emergency frame engraving from one body model to 3 body models,with the same head - trivalent -:

- without operator intervention.

- reducing errors.

- improving times.

With this improvement, we moved from three combustion car production lines to one, leaving room for the inclusion of a new production line for electric vehicles.

Backup and rework system incorporated in the same installation.

With this improvement, we moved from three combustion car production lines to one, thus making room for the inclusion of a new electric vehicle production line, automating the process, improving times and reducing errors.

Trivalent scoring head

The frame engraving of the three models has been unified in a single head.

A backup and rework system is incorporated in the installation itself, allowing the engraving of vehicles both on and off the production line.

Chassis scratch engraving unit.

XY scratch engraving system, motorized tool with motors and spindles in the XY, pneumatic Z system.

- Engraving control software.

- Special system of clamping flange and support engraving.

- Automatic centering system by means of mobile elements that are positioned according to the model.

- Process quality detection.

Weightless manipulator with pneumatic locking rotation system.

The weightless manipulator is coupled to an XY Cartesian, which together with the rotation system integrated in the manipulator itself, allows the operator to move and rotate the entire head 180º, thus being able to engrave vehicles that are in the production line or outside it.

- Cartesian XY system.

- Pneumatic locking rotation system.

- Z axis by means of pneumatic weightless.

- Screen.

The referencing elements are automatically adjusted to the position.