FOOD TRANSPORT - AUTOMATION ORBITAL ROLLERS

Installation in which the output of the product sachet lines is automated and palletised. There are three product infeeds with a maximum rate of 90 sachets per minute. On the other side of the line there is a supply of pallets, empty boxes and output of palletised product.

Installation in which the output of the product sachet lines is automated and palletised. There are three product infeeds with a maximum rate of 90 sachets per minute. On the other side of the line there is a supply of pallets, empty boxes and output of palletised product.

The line infeeds have a second belt on which the bags are deposited while the cartons are being changed, acting as a buffer and avoiding production stoppages.

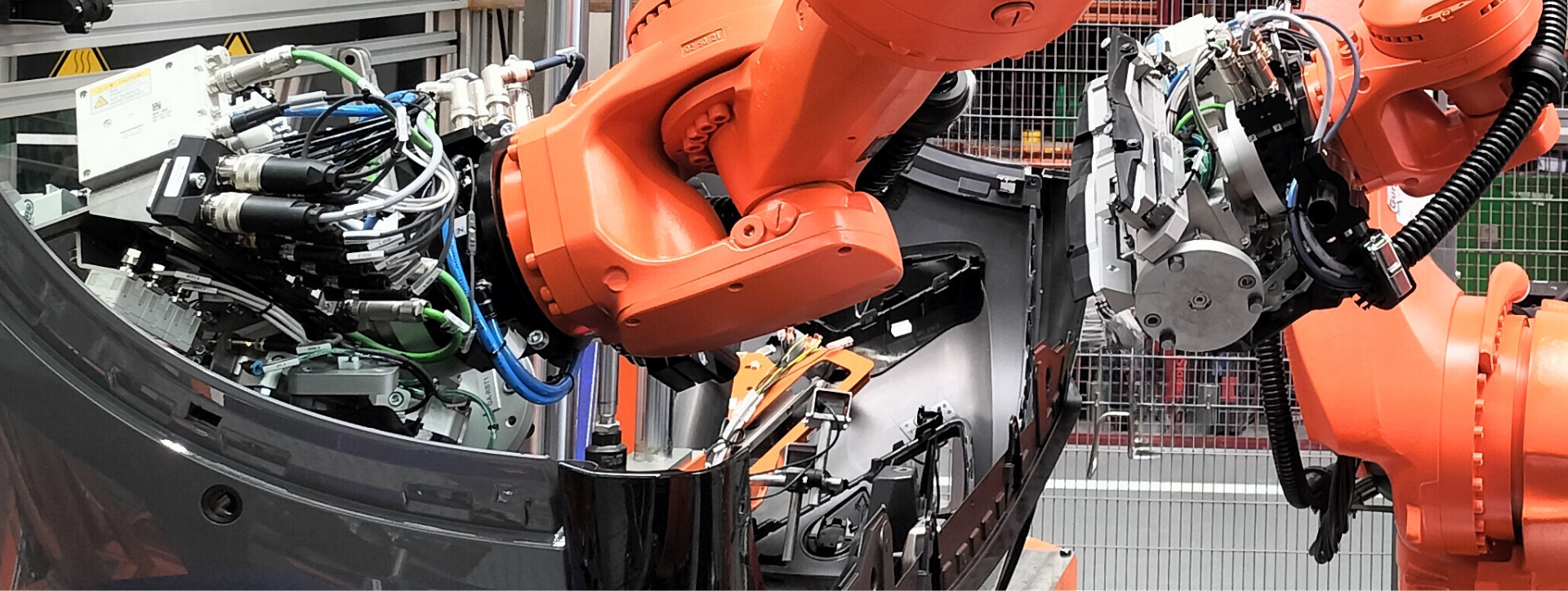

The grippers of the palletizing robots are equipped with Cognex vision cameras that have a dual function:

- To ensure the picking up of empty cases.

- To ensure the drop and stacking of one box on top of another since these boxes are recessed.

ORBITAL SYSTEM:

System with bearings and eccentric motor that produces an orbital movement to distribute the bags homogeneously on the box. - Weighing system composed of three cells for filling the product bucket in dynamic. ROBOTS

CLAWS:

Gripper system with centering by handles. - Cognex vision camera system to control the picking and dropping of the stacked boxes.