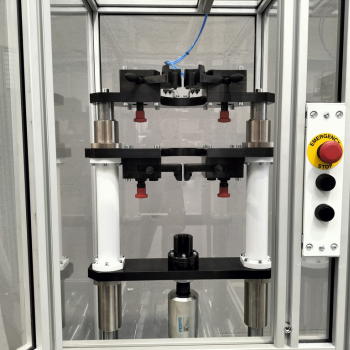

CIRCLIP STRETCHED TEST BENCH

Semi-automatic workbench developed for the on-site testing of circlip, by means of pneumatic traction at 1000 Kg at the ends of the product.

Semi-automatic workbench developed for the on-site testing of circlip, by means of pneumatic traction at 1000 Kg at the ends of the product.

TOTAL QUALITY CHECK

The system is based on a mechanism governed only by pneumatics.

The presence of the circlip is checked visually. If there is disassembly between the parts of the product when traction is applied, it means that there is no circlip.

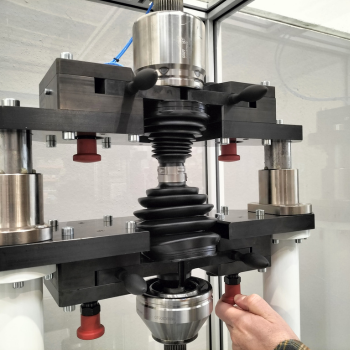

SUPPORT AND TOP CLAMPING

The system combines a mechanical locking by means of two flanges and two lower locks to check its correct position for the work.

The system has a pneumatic lever valve per flange that ensures the correct position for safety when applying traction.

STRETCHED CARRIAGE AND LOWER CLAMPING

The system combines a mechanical locking by two flanges and two lower locks to check its correct position for the work.

This system is guided by ball cage bushings to ensure alignment when applying the 1000 kg pull.

PNEUMATIC TRACTION

The actuation system on the drawing carriage is a double-acting pneumatic cylinder, with a thrust force of 1000 Kg, governed only by pneumatics.