Solución

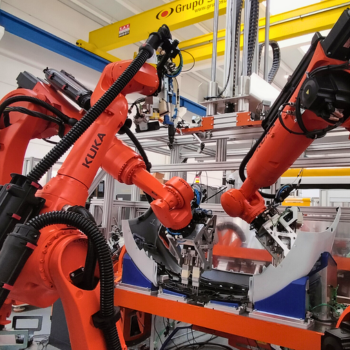

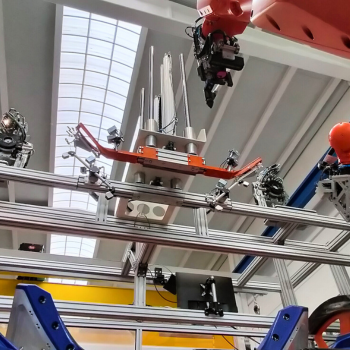

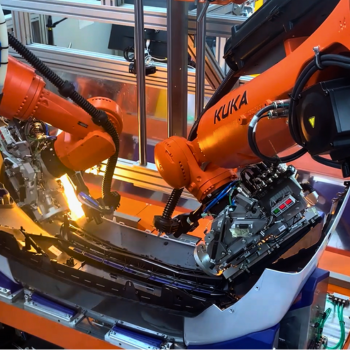

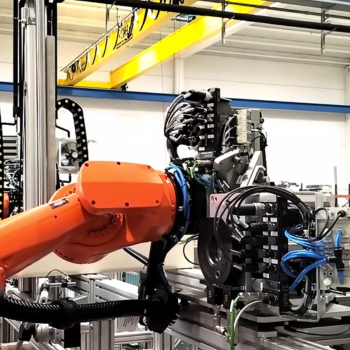

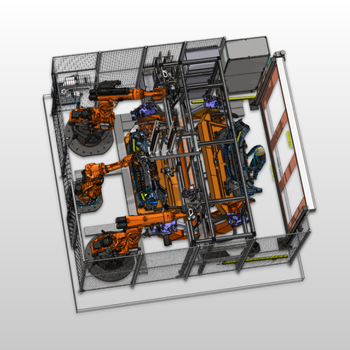

Robotized cell that performs the three functions of clipping, gluing and screwing at the same time thanks to:

- Synchronous work of 3 robots in automatic mode.

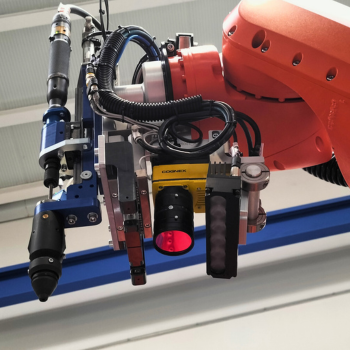

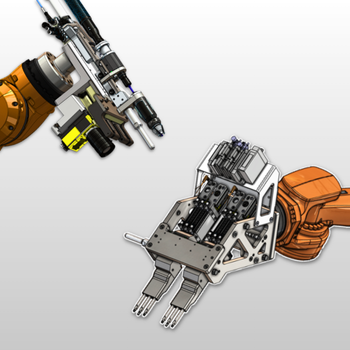

- A gripper changeover system that allows the robots to perform different operations in the same cell.

- Interaction with an operator working manually from a rotary table, protected by a safety barrier.

- A verification system using artificial vision.

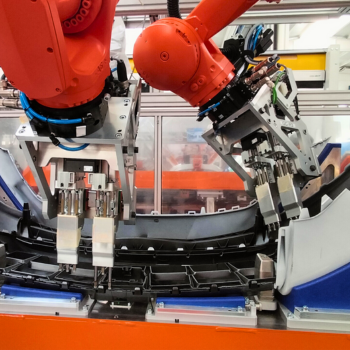

CRADLE (100% detection)

The cradle guarantees the correct positioning of the different parts of the product and detects all the elements of the product, ensuring repeatability in the process.

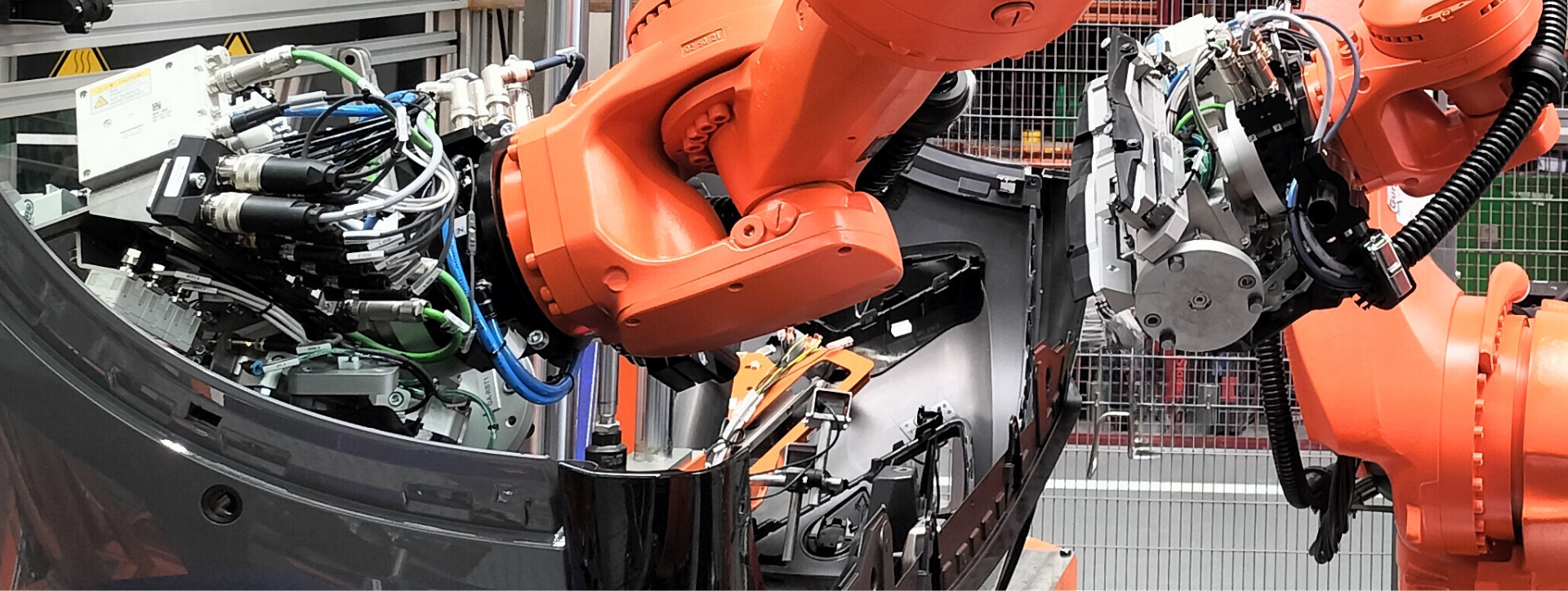

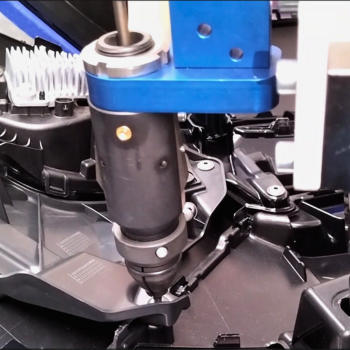

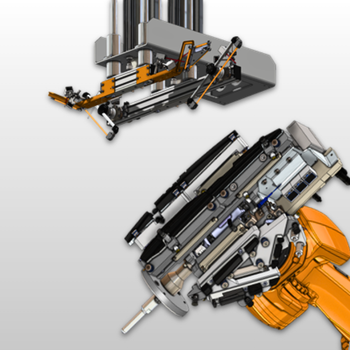

BONDING

The system is equipped with an IR lamp heating system to ensure the correct temperature of the parts at the moment of application with the gluing claw.

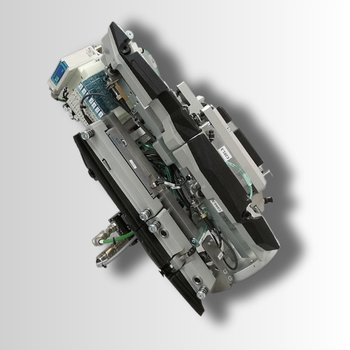

CLIPPING

The system is equipped with a clipping claw consisting of a group of individually operated clippers to be able to clamp each part to be clipped at different stages of the process.

Ventajas

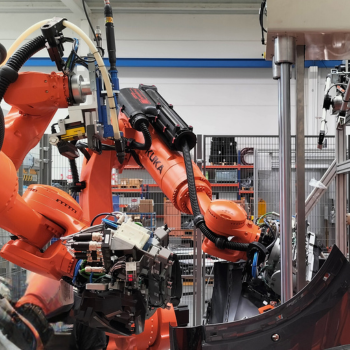

100% security, since the machine is protected with perimeter enclosure, security barrier and automatic door.

Productivity improvement, the robotic cell allows to work simultaneously with 3 robots and an operator on both sides and different part models.

Quality improvement, the position controls of the cradle and robots ensure the repeatability of the process and the correct assembly of the parts, thus avoiding future rejects.